A brief introduction to the characteristics and application of PTFE special-shaped parts

Classification:

Industry dynamics

Author:

PFA tube little sister

Source:

Dankai

Release time:

2023-01-10

Visits:

Dankai PTFE special-shaped parts are molded into blanks using high-quality PTFE resin according to product specifications, and are processed by turning, milling and finishing.

Dankai polytetrafluoroethylene (PTFE/TEFLON) is the most widely used and the largest number of fluorine-containing plastics. It has excellent comprehensive properties: high and low temperature resistance, corrosion resistance, and aging resistance.

chemical, non-adhesion, high insulation, high lubrication, non-toxic. Widely used in chemical industry, machinery, bridges, electric power, aviation, electronics and other fields, is the most ideal of modern industrial civilization

One of the engineering materials.

Heat resistance: has excellent resistance to high and low temperature characteristics. Generally, it can be used continuously between -180 ℃ ~ 260 ℃, has remarkable thermal stability, and can work at freezing temperature.

No embrittlement, no melting at high temperatures.

Corrosion resistance: almost no chemical and solvent erosion, can protect parts from any kind of chemical corrosion.

Atmospheric aging resistance: long-term exposure to the atmosphere in the surface and performance remains unchanged.

Non-stick: Has the smallest surface tension in solid materials without adhering to any substance.

Insulation: with strong dielectric properties (dielectric strength of 10kv/mm).

Lubrication, wear resistance: has a low coefficient of friction. The coefficient of friction changes when the load slides, but the value is only between 0.04 and 0.15, precisely because of its strong lubrication.

Slippery, which is also very prominent in wear resistance.

Non-toxic: with physiological inertia.

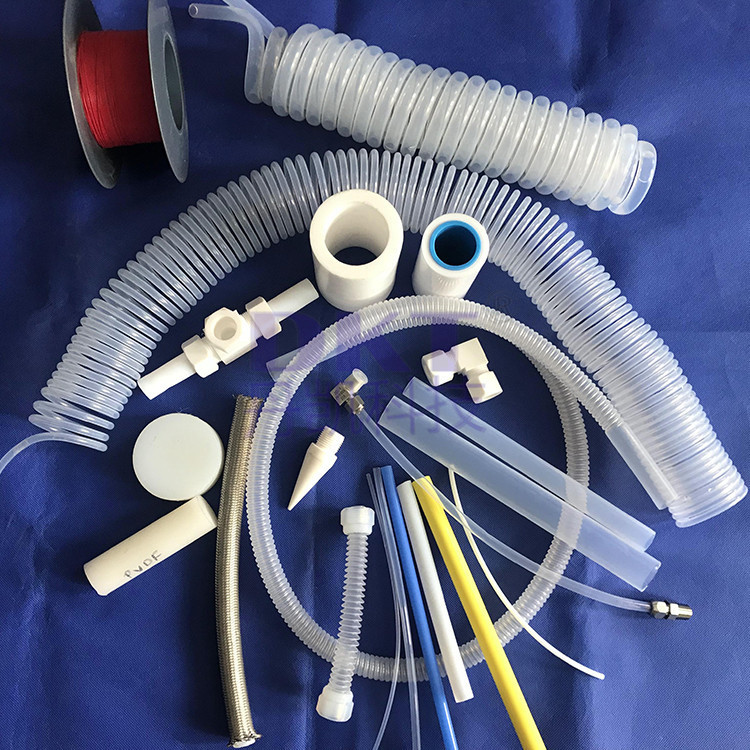

Figure 1: Teflon tube Source: Dan Kai

Application

1. Used in the electrical industry, in aerospace, aviation, electronics, instrumentation, computer and other industries used as power and signal line insulation, corrosion-resistant, wear-resistant materials can be made of film, tube sheet

Bars, bearings, gaskets, valves and chemical pipelines, pipe fittings, equipment container linings, etc.

2. Used in electrical appliances, chemical industry, aviation, machinery and other fields instead of quartz glassware used in atomic energy, medicine, semiconductor and other industries of ultra-pure chemical analysis and storage of various acids,

Alkali and organic solvents can be made into high-insulation electrical parts, high-frequency wire and cable wrapping, corrosion-resistant chemical utensils, high-cold-resistant oil pipelines, artificial organs, etc. can be used as plastics, rubber

Glue, paint, ink, lubricating oil, grease and other additives.

3. This product has high temperature resistance, corrosion resistance, excellent electrical insulation, aging resistance, small water absorption and excellent self-lubricating performance. It is a general-purpose lubricating powder suitable for various media.

At the end, it can be quickly applied to form a dry film to be used as a substitute for graphite, molybdenum and other inorganic lubricants. Release agent for thermoplastic and thermosetting polymers with excellent load-bearing capacity

Good. It is widely used in the elastomer and rubber industries and in corrosion protection.

4. Used as a filler for epoxy resin to improve the wear resistance, heat resistance and corrosion resistance of epoxy adhesives.

5. Mainly used as a powder cake binder and filler.

This article is originally created by Teflon's little sister. Welcome to pay attention and take you to grow knowledge together!

Key words:

PTFE, high and low temperature resistance, aging resistance, high insulation, high lubrication, non-toxic, insulation