What is the difference between PTFE and FEP?

Classification:

Industry dynamics

Author:

PFA tube little sister

Source:

Dankai

Release time:

2023-01-11

Visits:

1. Different characteristics

Dankai PTFE material has the characteristics of acid and alkali resistance, resistance to various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance,

Its coefficient of friction is very low, so it can be used for lubrication, but also become an ideal coating for easy cleaning of the inner layer of the water pipe.

FEP can be applied to soft plastics, the tensile strength, wear resistance, creep resistance is lower than many engineering plastics. It is chemically inert and has

Lower dielectric constant. The material does not ignite and can prevent the spread of flame. It has excellent wear resistance, low friction coefficient, from low temperature to high temperature can be used.

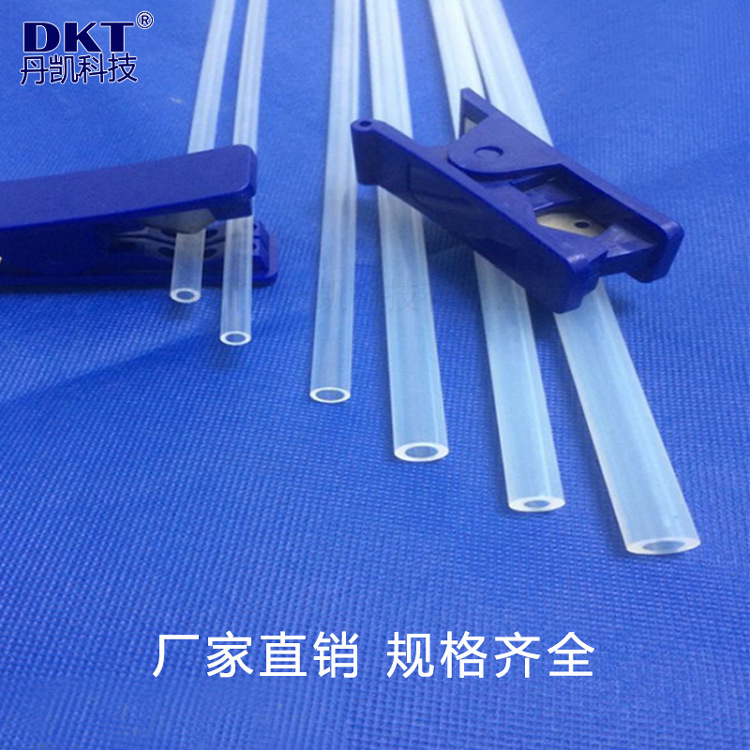

Figure 1: FEP tube Source: Dankai

2, the scope of application is different

PTFE has the advantages of the most significant resistance to voltage strength and breakdown voltage. Used for capacitor dielectric, wire insulation, electrical instrument insulation, sealing gasket. Polytetrafluoroethylene

An oriented film formed by the calender of the alkene turning film by hot roll rolling, which has high crystallinity, tightly arranged molecular orientation, small void ratio, and thus polytetrafluoroethylene film.

It is greatly improved, especially the anti-voltage strength is more obvious. Widely used in light industry, military, aerospace, oil and other fields.

FEP This material can be made into granular products for extrusion and molding, as powders for fluidized beds and electrostatic finishes, and as aqueous dispersions. Semi-finished products have film, plate. its main

It is used to make the lining of pipes and chemical equipment, the surface layer of rollers and various wires and cables, such as aircraft hook lines, booster cables, alarm cables, flat cables and oil wells

Well logging cables. FEP films have been used as thin coatings for solar collectors.

Figure 2: PTFE tube Source: Dankai

3. Different production classifications

FEP according to processing needs can be divided into three kinds of pellets, dispersion and paint. Among them, the pellets according to their different melt index, can be used for molding, extrusion and injection molding;

Impregnation and sintering; paint for spraying, etc.

PTFE color film is made of suspended PTFE resin to add a certain amount of colorant after molding, sintering to make blanks and then turning, calendering to make red, green, blue,

Yellow, purple, brown, black, orange, white and other 13 colors of PTFE oriented or non-oriented color film. Although a certain amount of colorant is added to the Dankai PTFE color film

After that, it still has good electrical insulation, which is suitable for insulation and classification identification of wires, cables and electrical devices.

This article is originally created by Teflon's little sister. Welcome to pay attention and take you to grow knowledge together!

Key words:

Fep, teflon, cable, film, with, oriented, made, different, dispersed

Previous Page