What are the advantages and disadvantages of PFA joint flaring and bead entry?

Classification:

FAQ

Author:

Teflon tube little sister

Source:

Release time:

2023-03-25

Visits:

What are the advantages and disadvantages of PFA joint flaring and bead entry?

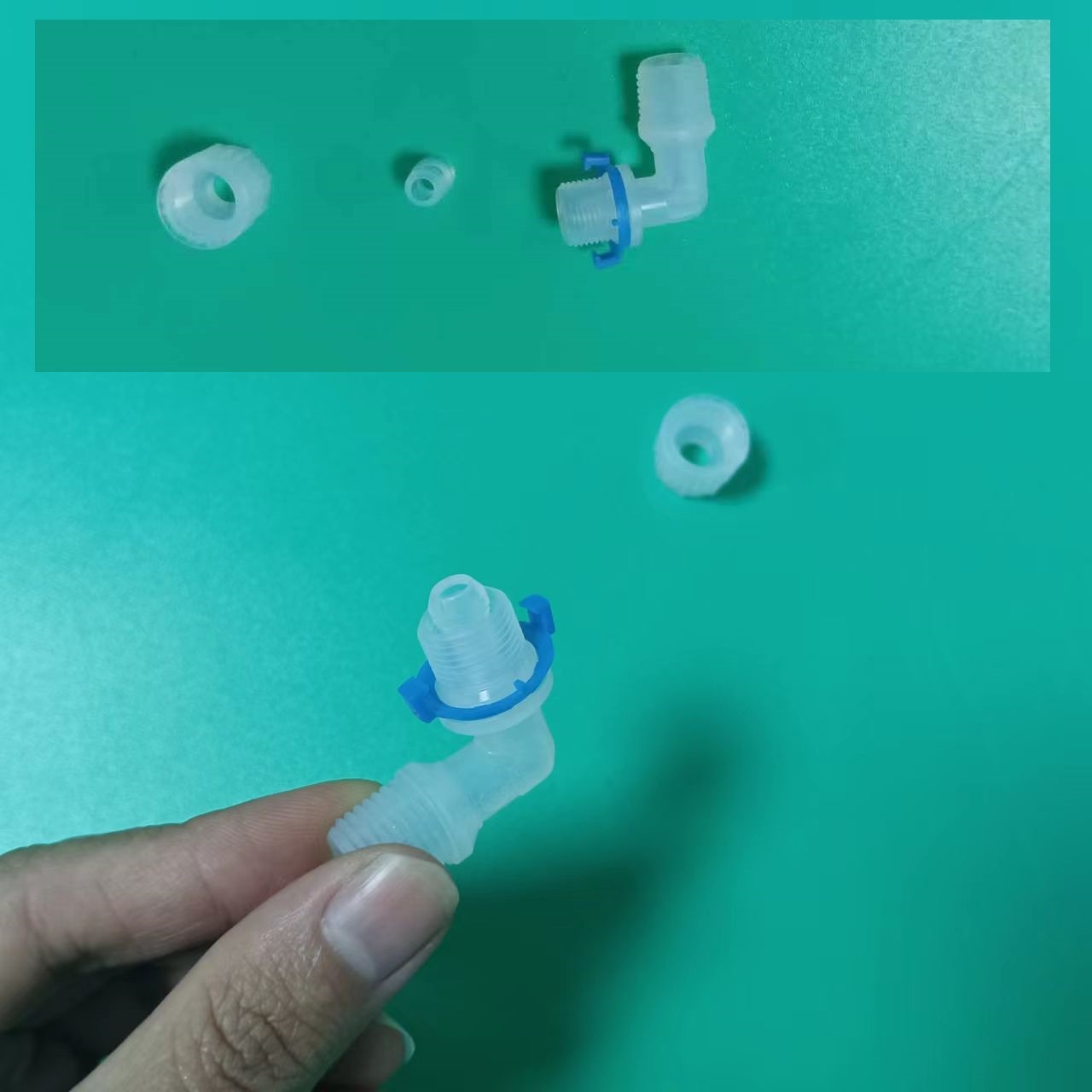

There are generally two forms of PFA joints, which are commonly used thermal expansion or flaring and bead entry. What are the advantages and disadvantages of the two? Especially the comparison of sealing?

PFA Flaring Fitting vs PFA Bead Fitting

1. Dankai PFA flare fitting:

-Advantages: better sealing, can withstand high temperature and chemical corrosion, easy to install and disassemble.

-Disadvantages: Not suitable for high-pressure applications, sometimes it is necessary to use O-rings to strengthen the seal.

2. Dankai PFA bead fitting:

-Advantages: Suitable for high-pressure applications, with good sealing and firmer connection.

-Disadvantages: More stringent processing requirements are required, installation and disassembly are more complicated, and it is easy to cause leakage.

Comparison summary:

-Dankai PFA flare joint suitable for general low pressure, temperature and flow requirements of the occasion.

-Dankai PFA bead fitting is suitable for applications under harsh conditions such as high pressure, high temperature and high viscosity.

-In general, which connector to choose should be determined according to actual needs and application scenarios.

This article is originally created by Teflon's little sister. Welcome to pay attention and take you to grow knowledge together!

Key words:

Joint, pfa, application, high pressure, sealing, mild, need, general, advantages